- GH-8 consists of various kinds of compounds, such as gluconate and low molecular weight organic acids.

- Non-poisonous, non-odor, and non-corrosivity.

- Normal dosage: 0.5% ~ 2.0% ( BWOS ). The amount can be appropriately increasea with the increase of temperature.

- It can reduce the consistency of cement slurry and improve the rheology.

- Retard the thickening time efficiently.

- Generally used in oil wells whose circulate temperature under bore is between 110℃ to 160℃.

High Temperature Retarder for Oil Well Cementing

Product Description :

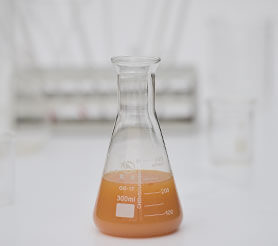

GH-8 can stick on the surfaces of cement hydrate to inhibit contacting between cement and water, also stick on the surfaces of crystal nucleons to prevent their enlarging. So it can retard hydrating of cement slurry.

Performance Characteristics :

Technical indicators :

| Items | Specification | |

| Solid | Liquid | |

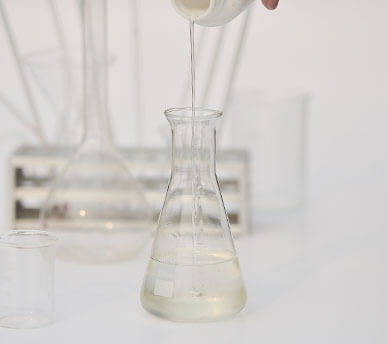

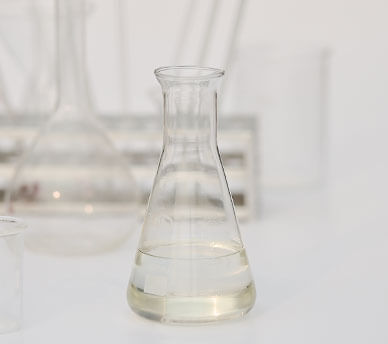

| Appearance | White powder | Colorless liquid |

| Thickening time | Adjustable | |

| Initial consistency, Bc/120℃, 73.9MPa, 61min | ≤ 30.0 | |

| Mutation value of thickening curve, Bc | ≤ 10.0 | |

| Transition time, min | ≤ 40.0 | |

| Free liquid, % | ≤ 1.4 | |

| Compression strength, MPa/144℃, 21MPa, 48h | ≥ 14.0 | |

The ingredient of cement slurry in the table is: JiaHua G class 594g + silica sand 208g ( 160 ~ 200 mesh ) + G301: 1.0% ( BWOS ) + distilled water: 333g +GH-8: 1.0 ~ 2.5% ( BWOS ) .

Packaging, storage and transportation :

- The solid be sacked with three-layer plastics bag, 25kg per bag, the liquid be stored in plastic barrel, 25kg per barrel.

- Be kept away from moisture and possible damage of the packages in transportation, be stored in cool and dry situation.

- Storage life time of solid product is two years, storage life time of liquid product is one year.