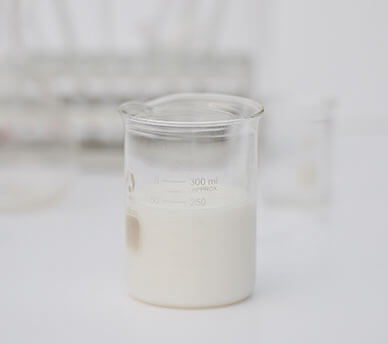

GH-9 consists of sulfonate and organic salts.

The density is about 1.20 g/cm³.

Normal dosage: 0.3% ~ 2.5% ( BWOC ).

Suitable temperature: 60℃ ~ 180℃ ( BHCT ).

It is used in the medium and deep well. It can prolong the thickening time effectively and increase the pumped time. It can formulate a right angle thickening cement slurry system.

If there is the a settlement phenomenon happened to the cement slurry because of its strong dispersion performance, the appropriate amount of G302 ( oil well cement fluid loss additive ) can be added to the cement slurry.